Muminda mizhinji senge kugadzirwa kwemaindasitiri, dziviriro yezvivakwa, fenzi yekurima uye yekushongedza imba, welded mesh yave imwe yezvinhu zvisingakoshike nekusimba kwayo kwechimiro uye kushandiswa kwakakura. Kiyi yekugadzikana uye kusimba kwewelded mesh munzvimbo dzakasiyana siyana iri mune yayo yakasarudzika uye inoyevedza dhizaini. Ichi chinyorwa chichaongorora zvakadzama kusimba kwesimba re welded mesh uye kuburitsa chakavanzika kuseri kwekuoma kwayo.

1. Manufacturing process uye basic structure yewelded mesh

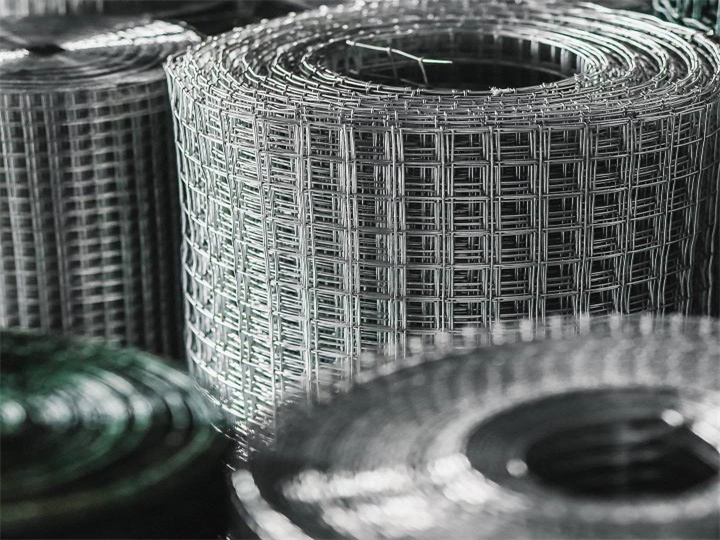

Sezvinoratidzwa nezita racho, welded mesh chimiro chemesh chinogadzirwa ne-cross-welding simbi waya pamwe chete kuburikidza nemagetsi welding. Mukuita uku, waya dzesimbi dzinonyunguduka pakupisa kwepamusoro uye dzinobatana zvakasimba kuti dzigadzire node dzakasimba. Aya ma node haango wedzera kugadzikana kwema mesh, asi zvakare inova nechokwadi chekubereka kweiyo weld mesh kana yakatarisana nekunze kwesimba.

Iyo yakakosha chimiro che welded mesh inowanzo sanganisira mesh saizi, dhayamita yewaya yesimbi uye marongero enzvimbo dzewelding. Iyo mesh saizi inosarudza kupera kweiyo weld mesh, nepo dhayamita yewaya yesimbi inokanganisa zvakananga kutakura kwayo. Iyo marongerwo emapoinzi welding ine chekuita nekusimba kwese uye kusimba kweiyo weld mesh. Inonzwisisika welding dhizaini inogona kunyatso kuparadzira masimba ekunze uye kudzivirira kukuvadzwa kunokonzerwa nekushushikana kwenzvimbo.

2. Zvinhu zvakakosha zvesimba rekugadzirisa

Zvinhu uye dhayamita yesimbi wire:Zvishandiso zvesimbi zvakajairwa zvemambure akaiswa zvinosanganisira waya yakaderera-kabhoni simbi, waya yesimbi isina tsvina uye waya yesimbi. Metal waya dzezvinhu zvakasiyana-siyana zvine simba rakasiyana uye kusagadzikana kwekuora. Iyo yakakura dhayamita yetambo yesimbi, iyo yakasimba kutakura-kuremedza kugona kweweld mesh, asi iyo permeability ichaderedzwa zvinoenderana. Naizvozvo, pakusarudza mesh yakashongedzwa, zvinodikanwa kudzikamisa zvinhu zviviri izvi zvinoenderana neiyo chaiyo application mamiriro.

Welding process uye node simba:Iyo welding process yeweld mesh yakakosha pakusimba kwayo. Welding yemhando yepamusoro inogona kuve nechokwadi chekubatana kwakasimba pakati petambo dzesimbi uye kuumba node dzakagadzikana. Aya ma node anogona kunyatso fambisa uye kuparadzira kushushikana kana akaiswa pasi pesimba rekunze kudzivirira deformation kana kutyoka kwe mesh. Uye zvakare, iyo nhamba uye marongero ewelding mapoinzi anozokanganisawo simba rose reiyo welded mesh. Inonzwisisika welding dhizaini inogona kuwedzera kugadzikana uye kusimba kweiyo weld mesh.

Grid dhizaini uye kushandiswa kuchinjika:Iyo grid dhizaini ye welded mesh haingokanganisa aesthetics yayo chete, asi zvakare yakabatana zvakanyanya nesimba rechimiro. Madiki meshes anogona kupa dziviriro iri nani, asi anogona kupa imwe dhigirii yepermeability. Naizvozvo, kana uchigadzira welded mesh, zvinodikanwa kusarudza yakakodzera mesh saizi zvinoenderana nezvinodiwa zvechiitiko chekushandisa. Panguva imwecheteyo, iyo mesh dhizaini yeweld mesh inofanirawo kufunga nezve nyore kwekuiswa kwayo nekugadzirisa kuti ive nechokwadi chekugadzikana kwayo uye kuvimbika mukushandiswa kwenguva refu.

3. Kushandiswa kunoshanda kwesimba rechimiro che welded mesh

Kusimba kwesimba reweld mesh rakashandiswa zvakanyanya muminda yakawanda. Mumunda wekuvaka, welded mesh inoshandiswa sekusimbisa madziro, tsigiro yepasi uye fenzi yekudzivirira, uye chimiro chayo chakasimba chinogona kumira mitoro mikuru uye masimba masimba. Mumunda wekurima, welded mesh, sechinhu chefenzi, inogona kudzivirira zvinobudirira kutiza kwemhuka uye kupinda kunze kwenyika, uye kudzivirira kuchengetedzwa kwezvirimwa nezvipfuyo. Uye zvakare, welded mesh inoitawo basa risingadzokerike mukufambisa, migodhi, kushongedza kwemba nemimwe minda.

Nguva yekutumira: Jan-24-2025